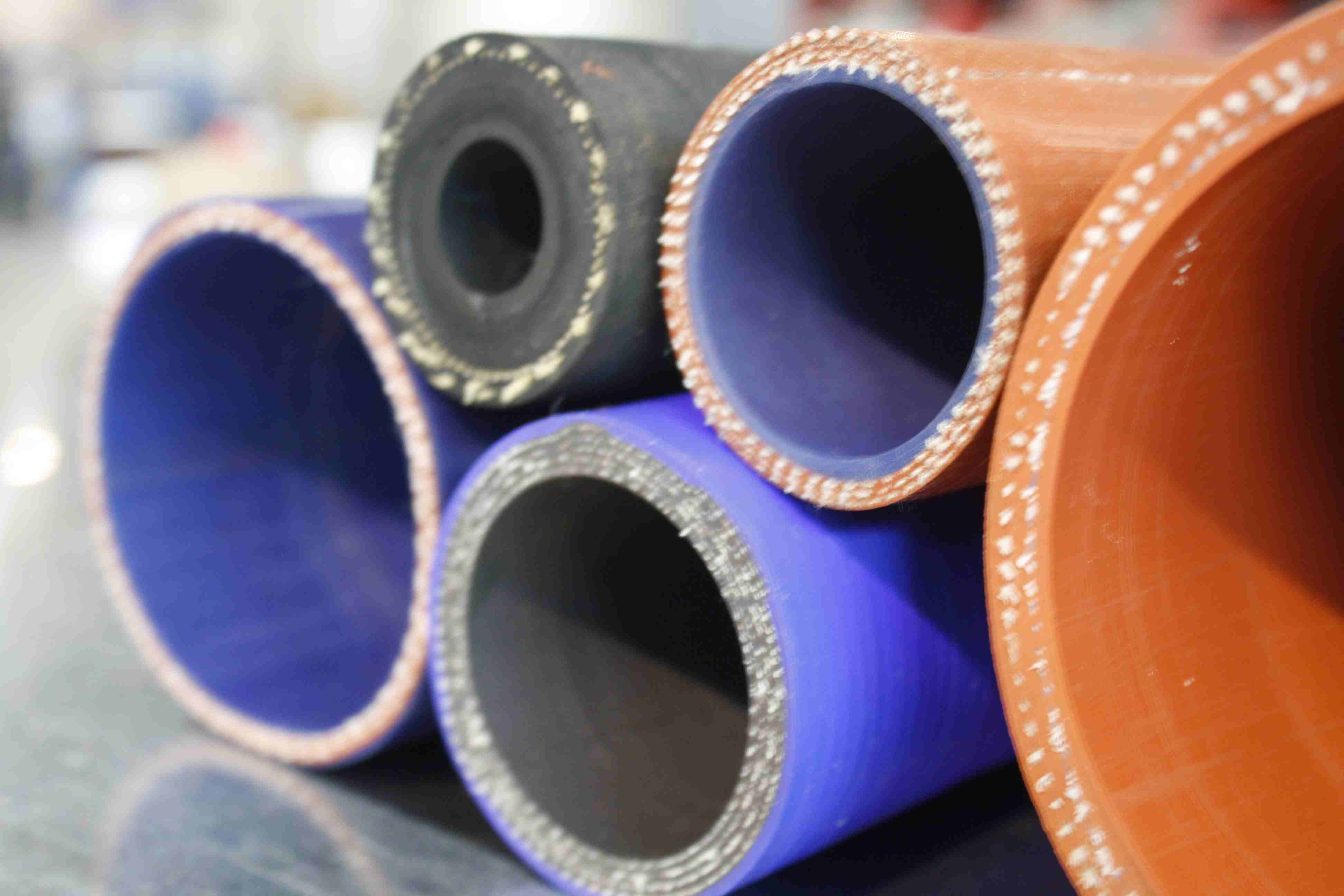

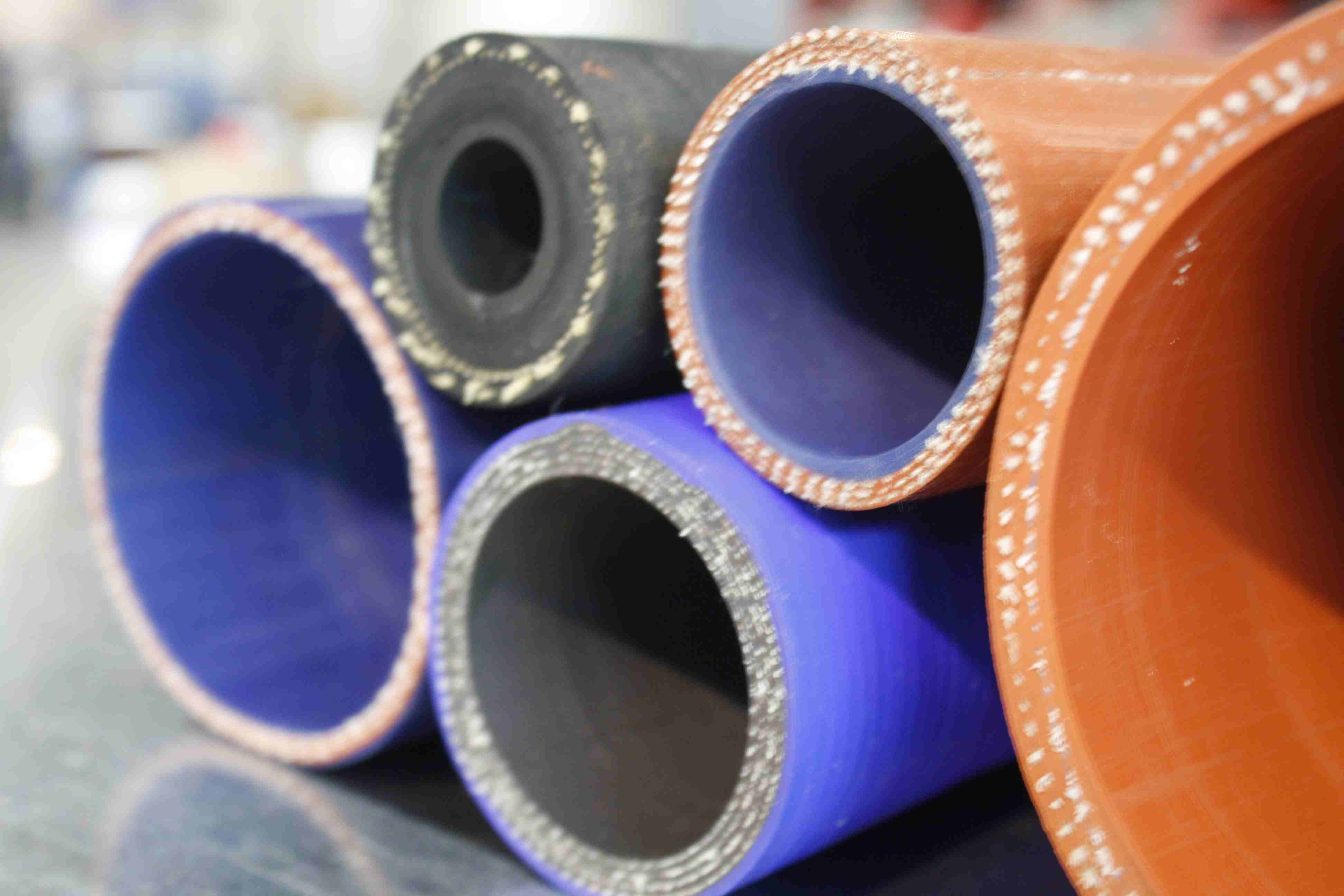

- All you need in rubber and silicone hoses

- Tailor made hoses

- We design your custom solution

- Every type of rubber, all kind of constructions

We are manufacturers of all our products. From the simplest hoses, from straight or elbow sections, to the most complex parts. Reinforced with steel wire, fabrics, a combination of different materials inside and outside, custom constructions. Extruded profiles and hoses. All materials, adjusted to each application and need.

VULCAX manufactures hoses, sleeves and elbows in rubber and silicone, with textile or spiral wire reinforcements and in short or even unitary series. Our products can be useful in several sectors. First equipment, custom or turnkey installations, industrial maintenance, industrial vehicle, vehicle and public works machinery, pumping equipment, mining, concrete industry, food industry, air conditioning installations ... All of them and many more value to solve a problem with a custom solution in rubber or silicone. Whenever it is necessary to conduct a more or less aggressive fluid, at higher or lower temperature or pressure, it will become necessary to use elbow hoses or rubber or silicone sleeves. If the consumption is appreciable, if the construction is standard and the application is within the usual range, you can and should go to standard hoses of one of the many manufacturers available in the market. Its quality and price are excellent. VULCAX can help you if the construction is special, the application is not standard, the quantity needed is small or even unitary. Where the catalogs of hoses, sleeves and elbows do not reach is where we work.

From the user's point of view, a hose is an element that conducts a fluid, flexibly joining two zones of a circuit. However for the manufacturer there are different types of hoses that differ by the type of construction or manufacturing method. At VULCAX we address all these types of hose with maximum flexibility and availability. We are able to manufacture the most complex hoses in short or even unitary series.

Rubber is an elastic polymer that historically is obtained as a milky, latex emulsion, a product of the sap of several tree plants, the main one currently being Hevea Brasiliensis. Latex was already used since ancient times by South American Indians who acquired extensive knowledge in its use including vulcanization processes through organic agents that achieved similar results to the current ones.

The modern and industrial use of rubber begins when the sulfur vulcanization process is discovered in the middle of the 19th century. During the following decades its uses begin to spread generating a growing demand for latex. Already at the end of the century, alternative sources of supply from petroleum by-products are being developed. Synthetic rubber is discovered and it becomes industrial and highly strategic as the car develops and especially as World War I begins and access to latex becomes increasingly limited.

The discovery of the vulcanizing process revolutionized the world industry. The small spaces between moving parts in the increasingly complex machines of the 19th century could only be closed with leather parts soaked in oils. Its performance was very poor and limited to low pressures and temperatures. The life and performance of the machines was reduced by increasing steam leaks. Vulcanized rubber came to solve the problem in an ideal way. Pieces formed with exact measurements could be manufactured withstanding large deformations under stress and recovering their dimensions by eliminating stress. If we combine this with its durability and lack of adhesion to the metal elements we get the perfect material for all sealing needs. Engineers were able to develop increasingly precise and efficient machines.

In the following decades, many materials and processes are developed that respond to a wide range of needs. Durability, resistance to chemical agents, high or low temperatures, mechanical demands, wear resistance ... All these properties and many more find their answer in one of the many rubbers available today or today. EPDM, NBR, CR, Viton, Silicones, Fluorsilicones ... They are widely used materials today. Also natural rubber or NR (Natural Rubber). In fact, the use of natural rubber produced from latex remains a massively used material today. Its production is in the hands of the large multinationals in the sector and the large tire manufacturers that control extensive plantations in Asia and South America.

The rubber is definitely a mixture of polymers that, by adjusting its formulation, the nature of impurities and additives achieves different properties. This mixture of polymers in "crude" is vulcanized to obtain the definitive properties of durability, mechanical properties and resistance to the required external agents. Vulcanization is a process that in the presence of sulfur, accelerated or delayed by additives and through high pressures and temperatures produces bonds between polymer chains through bridges of chains of sulfur atoms. The vulcanization process is also achieved by other means such as organic peroxides that produce rubbers with better mechanical characteristics and greater durability. Other rubbers such as chloroprene (neoprene) are vulcanized in the presence of metal oxides. Silicones with acetoxysilane ... This process is irreversible, and rubber is therefore a thermostable material. In fact, rubber recycling is one of the great technological challenges today. If this advance the tire cemeteries do nothing but grow only content by expensive and limited crushing and reuse processes.